Main Features

- Outside case made by high-quality Sheet steel

- High resistance to corrosion

- Diaphragm made by advance gluing and vulcanization process

- High accuracy and long reliability

- Low noise level

It is a compact residential gas meter designed to accurately measure volumes of natural gas, LPG and all noncorrosive gases. Its design minimizes installation costs and enables future field upgrades.

Application

The long-term metrology stability makes it the right choice for demanding, high consumption residential gas markets.

Metrology

During preliminary test bench controls, the meter is 100% tested according to customer or national requirements.The design and the careful materials selection enable it to meet the highest demand in international markets in terms of accuracy and long-term stability.During the preliminary test controls on the sonic nozzle test benches, all meters are tested at Qmin, 0.2 Qmax and Qmax.

Operating Principle

The meter is a positive displacement diaphragm gas meter with a stand-alone twin chamber measuring unit. The twin chambers are each fitted with a flexible and gas-tight diaphragm, which is moved by the differential between the inlet and outlet pressure. Gas enters one side of the diaphragm plate, while on the other side it sluice through a separate port on the valve. When one side is full, the rotating mono-valve moves on to the next position, allowing the gas to fill the empty side. A transmission gear and a mechanical coupling or stuffing box transfer the reciprocating motion to the mechanical index.The measuring unit is housed in a robust, gas-tight casing.

Technical parameters

Items | Unit | G10 | G16 | G25 | G40 | G65 | G100 | |

Nominal flow-rate | m3/h | 10 | 16 | 25 | 40 | 65 | 100 | |

Max flow-rate(Qmax) | m3/h | 16 | 25 | 40 | 65 | 100 | 160 | |

Min flow-rate(Qmin) | m3/h | 0.1 | 0.16 | 0.25 | 0.4 | 0.65 | 1 | |

Casing material | Steel | |||||||

Centre distance | mm | 180 | 220 | 280 | 430 | 480 | 520 | |

Total pressure loss | Pa | ≤300 | ≤400 | |||||

Max working pressure | bar | 0.5 | ||||||

Cyclic volume | dm3 | 5.0 | 8.0 | 20 | 30 | 55 | 88 | |

Error | Qmin≤Q<0.1Qmax | % | ±3 | |||||

0.1Qmax≤Q≤Qmax | % | ±1.5 | ||||||

Display range min. | dm3 | 2.0 | ||||||

Display range max. | m3 | 999999.99 | ||||||

Operation temperature | ℃ | -20~+50 | ||||||

Storage temperature | ℃ | -30~+60 | ||||||

Connection threads | G2 | G2 | G2 1/2 | G3 | DN80 | DN100 | ||

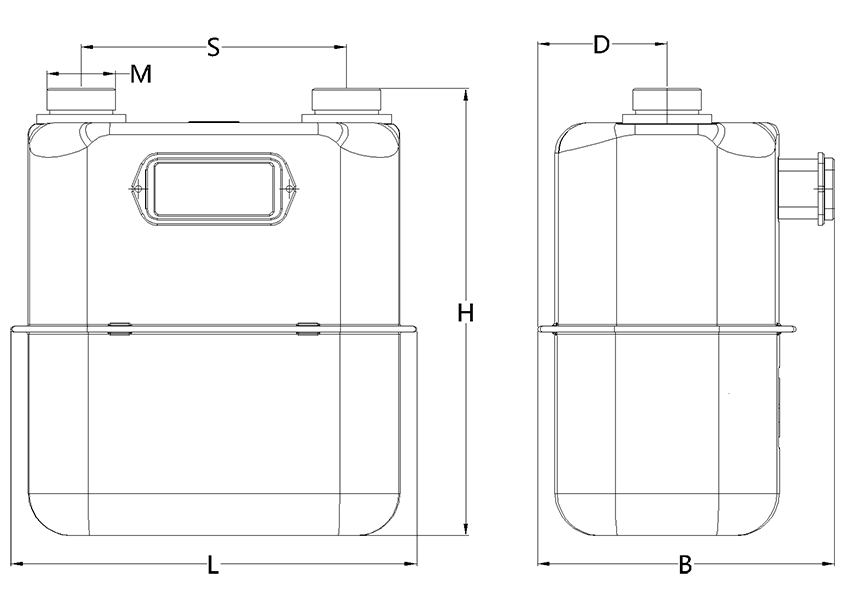

Sizes

Model | H | L | D | B | S | M | Weight |

G10 | 335mm | 284mm | 92mm | 217mm | 180mm | G2" | 4.30kgs |

G16 | 374mm | 333mm | 106mm | 243mm | 220mm | G2" | 7.6kgs |

G25 | 438mm | 412mm | 130mm | 289mm | 280mm | G2"1/2" | 14kgs |

G40 | 645mm | 615mm | 169mm | 352mm | 430mm | G3" | 27kgs |

G65 | 892mm | 764mm | 217mm | 471mm | 480mm | DN80 | 35kgs |

G100 | 892mm | 764mm | 217mm | 471mm | 520mm | DN100 | 62kgs |